The CNC milling machine plays a crucial role in modern mechanical engineering. This skilled worker operates highly precise machine tools that process complex workpieces with utmost accuracy. Their main task is to program, set up, and monitor computer-controlled milling machines.

At the core of its activity is the manufacturing of precision parts for various industries. The CNC milling machine transforms digital design data into real metal components, plastic parts, or other materials with the highest manufacturing quality.

Technical skills, spatial understanding, and attention to detail are key qualifications for a successful CNC mill operator in mechanical engineering. Mastery of modern technologies and precise work distinguish an outstanding skilled worker.

Key findings

- Precise control of computer-controlled milling machines

- Transformation of digital design data into real workpieces

- High-precision processing of various materials

- Decisive role in modern mechanical engineering

- Mastery of complex technical systems

Programming of CNC milling machines

CNC programming forms the core of modern manufacturing technology. Precise computer-controlled machining processes enable manufacturing companies to produce high-quality and complex workpieces.

Creation of CNC programs

Various software tools play a crucial role in CNC programming. CAD/CAM software assists professionals in creating precise machining programs through the following steps:

- Digital construction of the workpiece

- Conversion of the design into G-Code

- Simulation of the processing strategy

- Optimization of manufacturing parameters

Use of technical drawings

Technical drawings are fundamental for successful CNC programming. They contain all the necessary information about the geometry, dimensions, and tolerances of the part to be manufactured.

| Drawing element | Importance for CNC programming |

|---|---|

| Dimensions | Precise motion control |

| Tolerance specifications | Quality assurance |

| Surface structure | Tool selection and editing strategy |

The G-code functions as a universal programming language for CNC machines. It translates complex design data into precise movement instructions for milling tools.

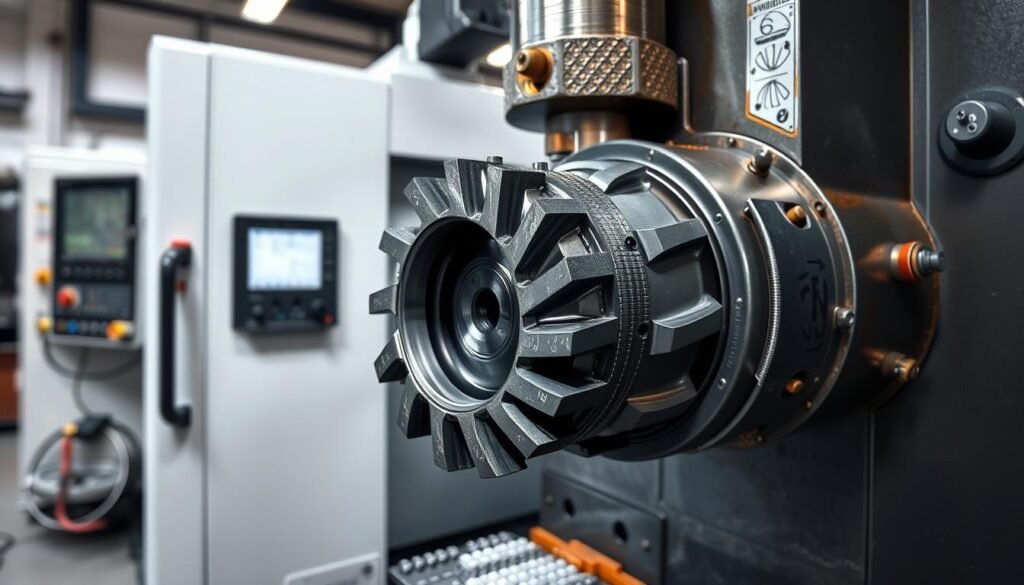

Setup of the CNC milling machine

The precise setup of a CNC milling machine is crucial for high-quality machining results. Professional tool management and careful machine setup form the foundation for efficient manufacturing processes.

Workpiece clamping: The foundation of precise machining

The correct workpiece clamping is one of the most important preparation steps. Clamping devices must meet the following criteria:

- Absolutely stable fixation of the workpiece

- No deformation during processing

- Simple and quick positioning

- Minimal vibrations during the milling process

Strategic Tool Selection

Several factors play a crucial role in tool management. The selection of the right tools directly affects the quality and efficiency of processing.

- Materials-specific tool selection

- Consideration of the cutting parameters

- Wear resistance of the tools

- Compatibility with the machine equipment

Precise machine setup

A professional machine setup includes the careful calibration and parameterization of the CNC milling machine. High-precision settings guarantee reproducible processing results.

Precise preparation is the key to success in CNC machining.

Operation and monitoring of the CNC milling machine

Process monitoring is a crucial aspect of operating CNC milling machines. Precise control and continuous monitoring ensure high-quality production results and minimize error risks during the machining process.

Continuous production process monitoring

Modern CNC milling machines are equipped with advanced monitoring systems that analyze various critical parameters in real time:

- Tool wear

- Cutting speeds

- Material stress pressure

- Temperature development

Ensuring product specifications

Multiple control mechanisms are implemented to ensure quality assurance and achieve precise manufacturing results:

| Control method | Description |

|---|---|

| Optical inspection | Digital image processing for defect detection |

| Dimensional measurement | Precise inspection of workpiece dimensions |

| Automatic correction mechanisms | Immediate adjustment in case of deviations |

"The accuracy of our machines defines the quality of our products." – Expert opinion from the manufacturing industry

Professional machine operation requires not only technical understanding but also continuous attention and training.

Quality control in CNC milling

Quality control is the core of precision machining in CNC milling technology. It ensures that every produced part meets the highest standards and fulfills the required specifications.

A systematic quality control includes various critical aspects of measurement technology and tolerance testing:

- Regular random inspections

- Precise measurements

- Documentation of the results

- Statistical Process Control

Random inspections

During random inspections, randomly selected workpieces are subjected to a comprehensive review. High-precision measuring instruments are used to detect even the smallest deviations.

Compliance with dimensions and tolerances

The tolerance test is a critical process in quality control. The following measurement methods are typically used:

| Measurement method | Accuracy | Scope of application |

|---|---|---|

| Digital caliper | ± 0.02 mm | Smaller precision parts |

| Micrometer screw | ± 0.01 mm | High-precision workpieces |

| Coordinate measuring machine | ± 0.005 mm | Complex geometric shapes |

Immediate corrective actions are initiated in case of deviations from the tolerances. This may involve readjusting the CNC milling machine or modifying the manufacturing parameters.

Quality control is not just an inspection but a continuous improvement process that ensures the efficiency and precision of production.

Maintenance and servicing of the CNC milling machine

Machine maintenance is crucial for the performance and longevity of a CNC milling machine. Professional maintenance strategies help minimize production downtime and maximize the machine's efficiency.

Preventive maintenance includes several critical aspects that need to be checked regularly. A structured maintenance approach can identify potential problems early and avoid costly repairs.

Simple maintenance work

- Regular lubrication of the moving components

- Inspection of wear parts

- Control of the electrical connections

- Inspection of the cooling systems

Machine cleaning

Cleaning procedures play a central role in machine maintenance. A clean CNC milling machine operates more precisely and reduces the risk of malfunctions.

| Cleaning area | Frequency | Method |

|---|---|---|

| Workspace | Daily | Suction of chips |

| Guide rails | Weekly | Cleaning and oiling |

| Electrical components | Monthly | Druckluft-Reinigung |

The combination of Preventive maintenance and thorough cleaning extends the lifespan of the CNC milling machine and ensures optimal production results.

Tool management for CNC milling

Tool management is a crucial aspect of CNC milling technology. An effective strategy for tool storage and wear monitoring can significantly improve the productivity and lifespan of precision tools.

Professional tool management includes several key components:

- Systematic condition check of the tools

- Regular wear monitoring

- Optimized tool storage

- Efficient documentation of tool statuses

Tool change

The tool change requires precise handling and care. Modern CNC milling machines feature automated exchange systems that enable quick and precise replacement processes.

Condition check

A careful wear monitoring helps to detect potential faults early. Technicians should regularly check tools for:

- Wear marks

- Micro damages

- Wear levels

- Material changes

Storage

Proper tool storage protects against damage and ensures long service life. Dust-free, dry environments with constant temperature are recommended.

"Precise tool management is the key to highest manufacturing quality" – Industry expert

Troubleshooting CNC milling

The fault diagnosis is a crucial aspect of machine optimization for CNC milling machines. Professional technicians must proceed systematically and precisely to quickly and effectively identify and resolve issues.

Troubleshooting CNC milling machines requires a structured approach. The following steps have proven effective in practice:

- Accurate error detection and documentation

- Systematic analysis of machine functions

- Identification of possible sources of error

- Development of targeted solution strategies

Error analysis

The fault diagnosis includes several important levels of investigation. Technicians need to critically examine various aspects of the CNC milling machine:

| Error area | Possible causes | Solutions |

|---|---|---|

| Mechanical components | Wear, bearing damage | Precise cleaning, replacement of defective parts |

| Control system | Software bugs, programming issues | Software update, re-calibration |

| Tool condition | Wear, damage | Regular inspection, timely replacement |

Troubleshooting

Machine optimization requires not only identifying problems but also systematically solving them. Preventive maintenance and continuous training are key elements of successful troubleshooting strategies.

Complex technical challenges should always be addressed in collaboration with experts to ensure the performance of the CNC milling machine.

Conclusion on the role of the CNC milling machine operator

The role of the CNC miller in the modern manufacturing industry is crucial and dynamic. Career prospects in this field require not only technical skills but also continuous education. Technological developments shape the future of CNC manufacturing and present professionals with exciting challenges.

Modern CNC milling machines must be flexible and willing to learn. Mastering complex machine technologies and precise manufacturing techniques forms the foundation for professional success. Digital skills and understanding of automated production processes are becoming increasingly important.

The future of CNC manufacturing will be shaped by innovations such as Industry 4.0, artificial intelligence, and connected production systems. Skilled workers who continuously update their skills and actively shape technological trends will be in high demand. The CNC miller is evolving from a pure machine operator to a strategic production expert.

Anyone interested in precision technology, technical understanding, and lifelong learning will find a future-oriented and fulfilling career perspective in CNC manufacturing with great potential for specialization and career development.