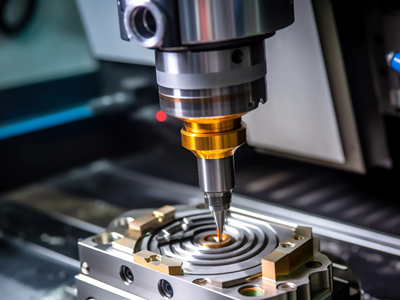

Precision milling of Partsproto – Highest quality from China for complex geometries and demanding applications

Rotary cutting tools are used in CNC milling to remove material from a workpiece to produce finished parts and products. This manufacturing process is great for many materials, including metals, polymers, wood, and glass.

CNC milling systems generally have 3 linear axes: the X, Y, and Z axes. This allows for the highest precision and detail accuracy. In addition, Partsproto offers more advanced 5-axis systems, where the tool head and the machine bed are also rotatable.

With 5-axis CNC machines, parts with high geometric complexity can be manufactured without multiple machine setups.

Standard milling with three linear axes for efficient processing of simple to moderate geometries.

Simultaneous 5-axis machining for complex geometries and hard-to-reach areas.

High-precision machining of small, complex parts with Swiss-type technology.

| Size | Metric units |

|---|---|

| Maximum part size for soft metals and plastics | 2000 x 1500 x 200 mm |

| Maximum part size for carbide | 1200 x 800 x 500 mm |

| Mindest-Merkmalsgröße | 0.50 mm |

| Size | Metric units |

|---|---|

| Maximum part size for all materials | 2000 x 1500 x 200 mm |

| Mindest-Merkmalsgröße | 0.50 mm |

We follow the ISO 2768 standards for CNC machining and guarantee the highest precision.

| Limit values for nominal size | Plastics (ISO 2768-m) | Metals (ISO 2768-f) |

|---|---|---|

| 0.5 mm* to 3 mm | ±0.1 mm | ±0.05 mm |

| over 3 mm to 6 mm | ±0.1 mm | ±0.05 mm |

| over 6 mm to 30 mm | ±0.2 mm | ±0.1 mm |

| over 30 mm to 120 mm | ±0.3 mm | ±0.15 mm |

| over 120 mm to 400 mm | ±0.5 mm | ±0.2 mm |

| over 400 mm up to 1000 mm | ±0.8 mm | ±0.3 mm |

*Please clearly indicate tolerances for nominal sizes below 0.5 mm in your technical drawing.

Standard surface finish directly from the machine

Corrosion protection and decorative surface for aluminum

Wear protection and improved conductivity

Corrosion protection for steel parts

Permanent and attractive color coating

Evenly matte surface texture

Structural parts, covers, engine components

Engine parts, transmission components, body parts

Implants, instruments, precision parts

Housing, heat sink, connecting elements

Guaranteed quality through certified processes and continuous improvement

Prototypes in 3-5 days, series parts in 1-2 weeks through optimized production processes

Up to 40% cost savings through direct manufacturing in China without quality loss

Tolerances up to ±0.01 mm through state-of-the-art CNC technology and experienced professionals

German-speaking customer service and technical support around the clock

100% Quality inspection with CMM measurement and detailed inspection reports

11 Longjiangyi Rd, Dong Guan City, Guangdong Province, United States, 523690

info@partsproto.de

Technical consultation and

Emergency hotline available