Silver is known for its shine and special properties. It is very valuable and used in many fields.

The Melting point of silver is very important. It determines how silver is used. This influences how it is processed and applied.

In this article, you will learn more about the silver melting point. It is important for everyone working with metals. Especially for metalworkers, engineers, and all interested in precious metals.

961 °C: Silver's properties

At 961 °C, silver melts. This temperature is important for many technical applications. Silver is known for its excellent physical properties.

It has high electrical and thermal conductivity. These properties make silver very versatile.

Conductivity and melting point

Silver conducts electrical and thermal energy best. This ability is very important for electrical engineering and electronics.

- High conductivity for efficient energy transfer

- Relatively low melting point for easy processing

- Ductility and corrosion resistance for durable products

The melting point of silver alloys can change. This is important for manufacturing.

You need to know the exact melting point. This applies to soldering, welding, and casting.

The thermal properties of silver are very important. They influence the material selection for technical applications.

Manufacturing requirements

Special requirements are important when processing silver. This ensures the quality and functionality of the components. There are many factors to consider to achieve the best results.

Surface treatment

Surface treatment is very important in silver processing. Polishing, gold plating, or protective coatings can improve silver. These methods increase the Conductivity and make silver more resistant to corrosion.

There are various methods to treat silver:

- Polishing: This makes the surface smoother and reduces electrical resistance.

- Gold plating: This makes silver more resistant and looks better.

- Protective coatings: These protect silver from oxidation and sulfide formation.

| Processes | Advantages | Applications |

|---|---|---|

| Polishing | Improved surface quality, reduced resistance | Electrical contacts, circuit traces |

| Gold plating | Increased corrosion resistance, improved appearance | Jewelry, decorative elements |

| Protective coatings | Prevention of oxidation and sulfide formation | Electronic components, contacts |

Avoid discoloration

Silver can discolor due to oxidation or sulfide formation. To prevent this, coatings or alloys are used. A controlled atmosphere during melting and processing helps preserve quality.

Modern techniques allow precise temperature control. This enables processing silver near its melting point without damaging its material properties. Proper procedures and treatments can improve the quality of silver components.

Practical applications

Silver is very important in industry. Its melting point and properties make it useful. It conducts well and is antibacterial.

Silver is highly valued in many fields, especially in medical technology and high-frequency technology.

Medical technology

Silver is popular in medicine due to its antibacterial properties. It is also biocompatible. Therefore, it is used in surgical instruments, implants, and coatings.

- Surgical Instruments: Silver is sterile and durable.

- Implants: Its biocompatibility is important for implants.

- Medical Coatings: Silver coatings prevent infections.

| Applications | Advantages | Properties |

|---|---|---|

| Surgical Instruments | Sterilizability, durability | Antibacterial, good conductivity |

| Implants | Biocompatibility | Good compatibility, antibacterial |

| Medical coatings | Infection prevention | Antibacterial, good adhesion |

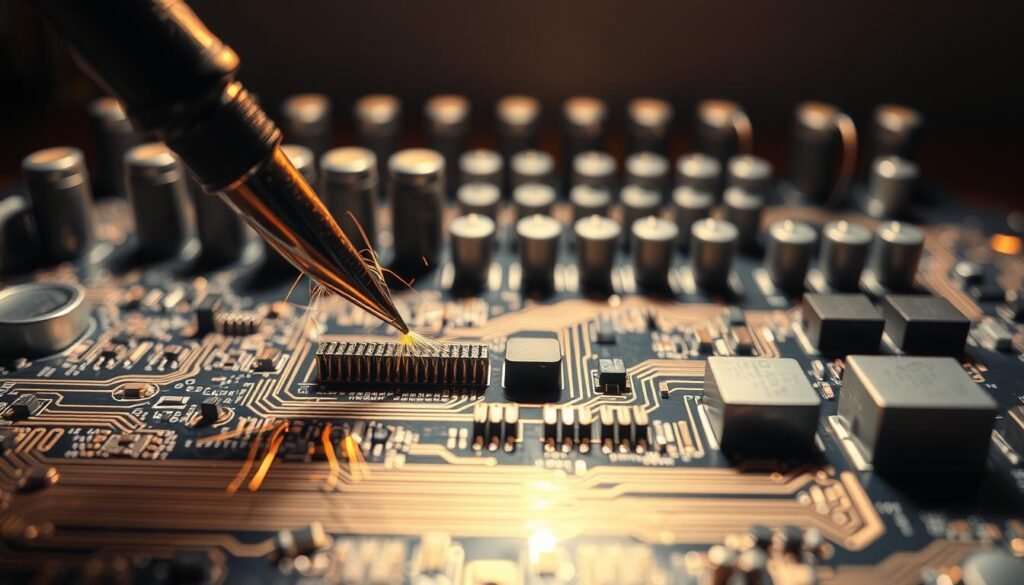

High-frequency technology

In high-frequency technology, silver is important because of its electrical conductivity. It is used in circuit boards, antennas, connectors, and resonators.

Precise processing of silver is important for the miniaturization of electronics. The melting point determines how much heat it can withstand.

Advantages for parts

Silver components are unique. They combine aesthetics, functionality, and precision. Their silver aesthetic makes them very popular for decorative and representative purposes.

Beautiful surfaces

There are various surface treatments for silver components. These enhance their aesthetic effect. Their functionality remains unchanged.

Functional properties

Silver is highly conductive electrically and thermally. It is also chemically resistant. This makes it ideal for demanding areas such as aerospace or energy technology.

High precision

The melting point of silver is exact. This allows for precise processing. Modern methods utilize silver's properties to create accurate parts.

Future developments could make silver even more useful. New silver alloys could expand its applications.