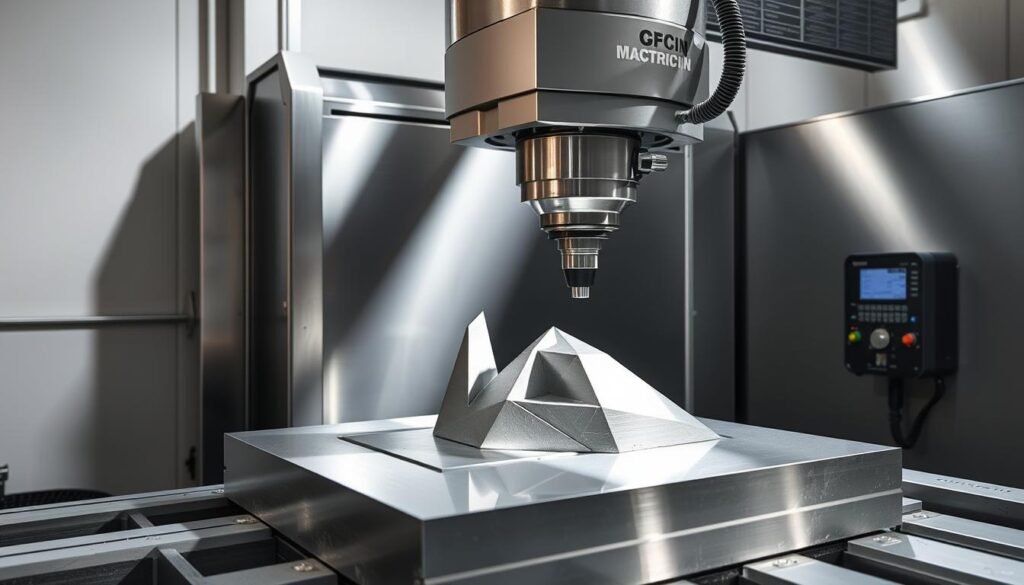

The CNC milling machine is a revolutionary tool in modern manufacturing technology. It enables precise and versatile CNC machining of various materials with the highest accuracy. The CNC milling machine applications range from simple workpieces to complex industrial components.

The CNC milling machine options are virtually unlimited. It can process metals, plastics, wood, and other materials with precise control. Professional craftsmen and industrial companies use this technology for high-quality manufacturing processes.

Key findings

- Precise material processing

- Versatile applications

- High manufacturing accuracy

- Automated production processes

- Complex form design possible

Material processing with the CNC milling machine

The CNC milling machine revolutionizes modern material processing through precise and efficient manufacturing techniques. With this state-of-the-art technology, craftsmen and engineers can work with various materials such as metals, plastics, and wood with exceptional accuracy.

The CNC milling machine materials include a wide range of materials that can be precisely processed thanks to computer-controlled operation. The flexibility of this technology allows professionals to create complex designs and high-precision components.

Key findings

- CNC milling enables precise material processing

- Different materials can be processed

- Computer-controlled technology improves manufacturing quality

- High repeatability of processing

- Suitable for various industries

Metals

The CNC milling machine metal processing offers precise possibilities for industrial manufacturing. Modern CNC milling machines enable the processing of various types of metal with the highest accuracy and efficiency.

In CNC milling metalworking, various materials play a crucial role. The most important metals for CNC milling include:

- Aluminum – lightweight and corrosion-resistant

- Steel – durable and versatile

- Brass – good conductivity

- Titan – highly durable

The choice of the right metal depends on the specific application. CNC milling of metals requires precise settings and specialized tools.

| Metal | Properties | Main applications |

|---|---|---|

| Aluminum | Light, corrosion-resistant | Aviation, Automotive |

| Steel | Feast day, economically | Mechanical engineering, design |

| Titan | Extremely durable | Medical technology, aerospace and aviation |

The precision technology of the CNC milling machine allows complex metal processing with minimal tolerances. Modern manufacturing techniques enable high-precision metal parts for demanding industrial applications.

Plastics

The CNC milling machine plastic processing opens up new possibilities for precision and efficiency in material processing. Different types of plastics are well suited for CNC plastic milling, including PVC, acrylic, and polyethylene.

When processing plastics, professionals must consider special challenges:

- Control of heat development

- Prevention of material deformation

- Selection of the right milling tools

- Precise cutting speeds

The selection of the right plastic is crucial for successful CNC plastic milling. High-performance plastics such as PEEK or polycarbonate require special processing strategies.

"Precision is the key to perfect plastic processing with CNC milling."

Modern CNC technologies enable extremely precise machining of plastic parts with minimal tolerances. The technology is suitable for small series as well as for custom prototypes.

Wood

CNC wood milling revolutionizes modern woodworking with the highest precision and efficiency. The CNC wood milling machine enables complex cuts and designs that would be impossible with traditional methods.

Different types of wood are suitable to varying degrees for CNC wood milling:

- Softwood like pine: easy to work with

- Hardwood like oak: higher precision required

- Exotic woods: demanding processing

The advantages of CNC milling wood processing include:

- High-precision cuts

- Repeatable results

- Complex geometric shapes

- Minimal material loss

Modern CNC wood milling can process wood panels with tolerances of less than 0.1 mm. This opens up new opportunities for craftsmen, designers, and industrial companies.

Shapes and details with the CNC milling machine

The CNC milling machine opens new dimensions of precision machining. With the latest CNC milling shaping, designers can create complex geometric structures with exceptional accuracy. The technology enables detailed CNC milling work that far surpasses traditional manufacturing methods.

The precision of a CNC milling machine allows the creation of shapes and details that were previously considered impossible. Modern machine technology combines computer-controlled operation with highly precise milling tools to handle even the most demanding design tasks.

Key findings

- Highest precision shaping with CNC technology

- Complex geometric structures possible

- Detailed processing of various materials

- High repeatability in manufacturing processes

- Flexible adaptation to different construction requirements

Complex shapes

The CNC milling machine enables the production of extremely precise 3D shapes with complex geometries. Modern technologies allow designers to realize even the most demanding geometric structures.

Several key factors play a crucial role in processing complex shapes:

- Precise CAD/CAM software programming

- High-quality CNC milling machine 3D mold technology

- Multi-axis movement capabilities

- High-precision tools

The development of CNC milling machines for complex geometries requires in-depth technical understanding. Designers must create digital 3D models that accurately represent the desired shape and structure.

| Complexity level | Required axes | Scope of application |

|---|---|---|

| Simple | 3-Achsen | Standard parts |

| Middle | 4-Achsen | Machine parts |

| Complex | 5-Achsen | Aerospace, Medical Technology |

The application areas for CNC milling 3D shapes are diverse. They range from prototype development to precision manufacturing in industries such as aerospace, medical technology, and mechanical engineering.

Grooves

The CNC milling of grooves is a highly precise machining technique that is critical in various industrial applications. With the CNC milling cutter, groove milling enables designers to produce extremely accurate guides, joints, and recesses in different materials.

- Highest precision in groove widths and depths

- Reproducible results in mass production

- Minimal tolerances of a few micrometers

- Quick processing times

Different nut types can be realized with CNC milling machines:

| Nuttyp | Scope of application |

|---|---|

| Rectangular nut | Mechanical engineering, electrical engineering |

| Kegelnut | Precision mechanics, Automotive |

| T-Nut | Tool manufacturing, robot technology |

The flexibility of the CNC milling machine slot milling allows precise processing in metals, plastics, and even wood. Designers can quickly and cost-effectively implement complex groove configurations.

Drilling

CNC milling drilling is a precise method for creating exact holes in various materials. The CNC drilling technology enables highly accurate and repeatable processing, which is indispensable in many industrial applications.

- Extremely high precision in hole creation

- Consistent quality across multiple workpieces

- Minimal deviations from the target size

- Quick processing times

In CNC milling, drilling techniques are distinguished:

- Through holesHoles that go completely through the material

- Blind hole drillingHoles with defined depth without passage

- Threaded holes: Precise threads for screw fastenings

The technology enables CNC drilling in materials such as metal, plastic, and wood with the highest precision. Each material requires specific drilling techniques and tool settings to achieve optimal results.

Other details

CNC detail milling enables precise machining that goes far beyond standard cutting techniques. Modern CNC milling machines can create extremely fine and complex details with the highest accuracy.

- Precise Engraving

- Complex surface structures

- Microscopically small contours

- Highly detailed geometric shapes

Various factors play a crucial role in CNC detail milling:

| Technical parameters | Significance for fine processing |

|---|---|

| Tool diameter | Definitely level of detail |

| Feed rate | Influences surface quality |

| Tool material | Decides on precision |

Modern CNC milling machines achieve tolerances in the Micrometer range, which makes them indispensable for precision industries. The technology allows extremely fine machining in a variety of materials such as metal, plastic, and ceramic.

Applications of the CNC milling machine

CNC milling has established itself as an indispensable technology in numerous industries. The versatile applications of CNC milling machines span various production areas and enable precise machining with the highest accuracy.

The importance of CNC milling machines becomes especially evident in modern manufacturing technology. Companies use this technology to produce complex parts and components that manual manufacturing methods cannot achieve.

Key findings

- CNC milling enables high-precision machining

- Applicable in various industries

- High reproducibility of workpieces

- Reduction of human error rates

- Economic manufacturing of complex components

Prototype development

CNC milling machine prototyping revolutionizes product development in various industries. This precise technology enables companies to quickly and cost-effectively create functional prototypes.

CNC prototype manufacturing offers key advantages for development teams:

- High precision with complex geometries

- Rapid iteration of product designs

- Minimal manual editing steps

- Cost reduction in the development process

In practice, engineers use CNC milling machine prototyping in industries such as:

| Industry | Typical applications |

|---|---|

| Automotive | Small series parts, body components |

| Aerospace | Lightweight components, precision parts |

| Consumer goods | Electronic enclosure, design prototypes |

The CNC prototype manufacturing accelerates innovation cycles and enables companies to develop market-ready products faster.

Mass production

The CNC series manufacturing revolutionizes the modern production landscape. Companies use CNC milling for mass production to develop precise and efficient manufacturing processes. This technology enables the production of large quantities with consistently high quality.

- Extremely high precision in manufacturing

- Consistent product quality

- Quick reproducibility of components

- Minimal manufacturing tolerances

For optimal CNC mass production, several strategies are crucial. Companies must precisely program the tool paths and develop highly efficient production processes. Automated tool changer and intelligent control systems improve overall efficiency.

The investment in modern CNC milling mass production enables companies to stay competitive. Through precise manufacturing techniques, complex components can be produced quickly and cost-effectively.

Custom parts

The CNC milling machine custom manufacturing opens up completely new possibilities for tailored components. Companies can develop precise and unique parts that exactly meet their specific requirements.

- Medical technology: Custom prosthetics and surgical instruments

- Mechanical Engineering: Special Machine Components

- Handicrafts: Unique design elements

The flexibility of CNC technology enables the production of complex geometries that would not be possible with traditional manufacturing methods.

"CNC milling revolutionizes the production of custom components through the highest precision and adaptability."

The core advantages of CNC milling custom-made products include:

- Extremely high manufacturing accuracy

- Rapid prototyping

- Cost-effective small-batch manufacturing

- Maximum design freedom

CNC customizations are especially suitable for projects that require unique technical solutions and where standard components are not sufficient.

Examples of CNC milling

CNC milling machine application examples demonstrate the incredible precision and versatility of modern manufacturing technologies. Professional workshops and production facilities use CNC milling machine projects to create complex workpieces in various materials.

The development of CNC milling technologies has revolutionized industrial production. It enables highly precise processing of various materials with minimal human intervention.

Key findings

- CNC milling enables precise material processing

- Wide range of applications in various industries

- High manufacturing accuracy and repeatability

- Economic solution for complex manufacturing processes

- Suitable for prototypes and mass production

Metalworking

The CNC milling machine plays a crucial role in metalworking. Precision and efficiency characterize modern CNC metal milling examples in various industries. Technicians use this technology to manufacture complex metal parts with the highest accuracy.

Important aspects of metalworking with CNC milling include:

- High-precision surface treatment

- Complex geometric shapes

- Minimal tolerance deviations

- Repeatable manufacturing quality

CNC milling machine metal parts are used in various sectors, including machinery manufacturing, aerospace, and the automotive industry. The technology enables the production of components with extreme precision.

| Industry | Typical applications | Materials |

|---|---|---|

| Mechanical engineering | Precision parts | Aluminum, steel |

| Aviation | Structural components | Titan, lightweight metals |

| Automotive | Motor components | Special alloys |

The processing of metal parts requires highly specialized CNC milling machines with advanced technologies. Modern machines can produce workpieces with tolerances in the micrometer range, which was not possible before.

Experts particularly appreciate CNC metal milling examples for their flexibility and precision. The technology allows the processing of various metal alloys with consistently high quality.

Plastic processing

CNC milling plastic parts play a crucial role in modern manufacturing processes. Precision technology enables the production of complex plastic components with the highest accuracy and repeatability.

The processing of plastics with CNC milling offers numerous advantages:

- High form accuracy

- Complex geometric structures

- Low material waste

- Rapid prototyping

Typical CNC plastic milling examples can be found in various industries:

| Industry | Application example |

|---|---|

| Medical technology | Precision parts for medical devices |

| Automotive | Prototypes of dashboards |

| Electronics | Housing for electronic components |

The selection of the right plastic material is crucial for successful CNC machining. Materials such as ABS, polycarbonate, and PEEK are especially suitable for precise milling work.

Modern CNC milling machines enable high-precision processing of plastic parts with minimal tolerances, making them an indispensable tool in industrial manufacturing.

Woodworking

CNC wood milling opens up a world of precision and creativity for craftsmen and designers. With a CNC milling machine, wooden parts can be produced with incredible accuracy and detail. The technology allows for the creation of complex designs that would not be possible with traditional methods.

Some key areas of woodworking with CNC milling include:

- Furniture manufacturing with precise joints

- Handcrafted decoration

- Individual furniture elements

- Architectural wood models

The versatility of CNC wood milling allows the processing of various types of wood such as oak, beech, maple, and exotic woods. Through computer-controlled precision, craftsmen can produce complex CNC-milled wood parts with minimal manual intervention.

Typical projects include:

- Individually designed wooden furniture

- Decorative wall panels

- Precise wood carvings

- Architecture models

The CNC wood milling examples demonstrate the incredible flexibility of this technology. From minimalist designs to complex three-dimensional structures, CNC milling offers unmatched precision in woodworking.

Other applications

The CNC milling machine demonstrates its versatility far beyond traditional manufacturing sectors. In the art scene, artists use this technology for precise sculptures and complex installations. Architects and designers utilize CNC milling machines for special applications to develop unique models and prototypes.

Surprisingly, the CNC milling machine is also making its way into unexpected industries. The food industry is experimenting with elaborate decorations and precise cutting techniques. Scientific laboratories are using this technology for highly precise research components and specialized tools.

CNC milling machines enable innovative projects and also allow creative solutions in areas such as medical technology and jewelry manufacturing. Orthopedic implants, custom prostheses, and finest jewelry pieces are made possible through this advanced technology. The boundaries of applicability are constantly being expanded.

The technology transforms almost every industry through its precision and flexibility. From space exploration to the fashion industry, the CNC milling machine opens new dimensions of manufacturing craftsmanship and innovation.