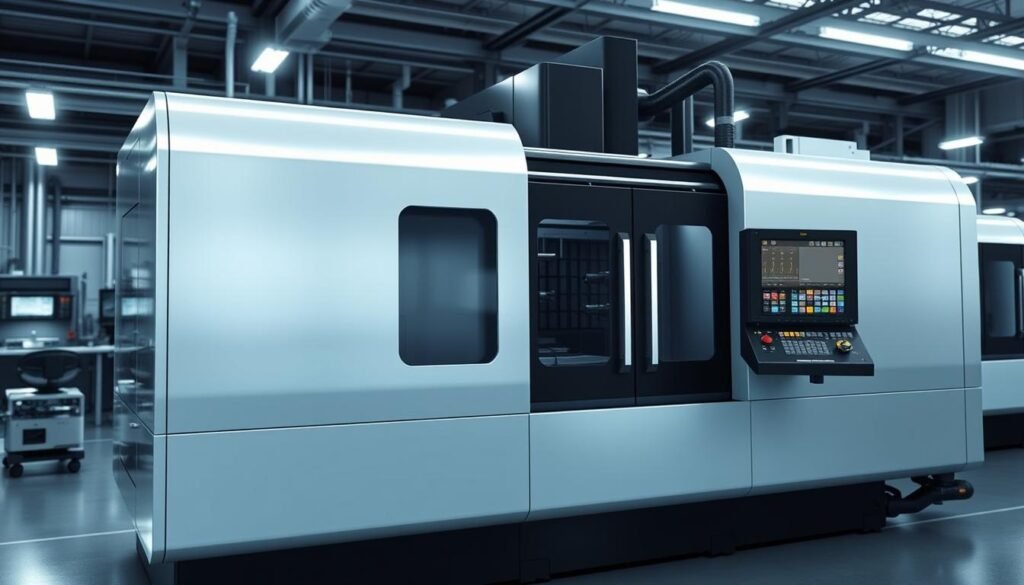

The modern manufacturing technology has revolutionized industrial production. A CNC machining center is a highly advanced computer-controlled machine tool that enables precise and efficient metal processing. These advanced systems have fundamentally changed traditional manual manufacturing methods.

The CNC machining center combines various processing operations in a single machine. It allows companies to produce complex workpieces with the highest accuracy and minimal human intervention. The flexibility and precision of these machines make them the backbone of modern industrial manufacturing.

Key findings

- High-precision computer-controlled machine tool

- Enables complex manufacturing processes

- Reduces human error rates

- Increases productivity and efficiency

- Versatile for use in various industries

Definition of a CNC machining center

A CNC machining center is a state-of-the-art precision machine that uses numerical control to perform complex workpiece machining. CNC technology enables exceptional accuracy and efficiency in industrial manufacturing.

- Computer-controlled control unit

- High-precision tool spindle

- Variable workpiece holder

- Automatic tool change system

The CNC-Technologie differs from traditional machining centers through its digital programmability. Through numerical control, complex machining steps can be executed precisely and repeatedly.

| Feature | Traditional machine | CNC machining center |

|---|---|---|

| Precision | Medium accuracy | Highest precision |

| Complexity | Limited processing steps | Multiple integrated processing steps |

| Programmability | Manual control | Fully digital control |

The workpiece machining with CNC-controlled centers enables unmatched accuracy and efficiency in various industrial applications.

Main features of a machining center

CNC machining centers are key technologies in modern precision machining. They combine advanced technologies to handle complex manufacturing tasks with maximum efficiency improvement. The main features make these machines indispensable tools in industrial production processes.

Computer-controlled control

The computer control system forms the core of a machining center. It enables precise control of all machine movements and processing steps. Through advanced software solutions, complex manufacturing tasks can be performed with the highest accuracy.

- Digital program control

- Real-time monitoring of processing procedures

- High positioning accuracy

Multiple editing steps

Manufacturing flexibility is achieved through the ability to perform multiple processing steps in a single setup. This reduces setup times and significantly increases productivity.

| Processing step | Functionality |

|---|---|

| Milling | Shaping and contouring |

| Drilling | Precise hole creation |

| Threads | High-precision reindeer breeding |

Automatic tool change

The automatic tool change is a crucial feature for optimized production. Tools can be changed quickly and precisely, minimizing processing time and increasing efficiency.

Complex geometries

Modern machining centers can process highly complex geometric shapes with astonishing precision. This opens up new possibilities in product development and manufacturing.

Applications of CNC machining centers

CNC machining centers play a key role in various high-tech industries. They revolutionize manufacturing processes in the automotive industry, aerospace, and medical technology through precise and efficient machining of complex components.

In the automotive industry, CNC machining centers are used for the production of critical components. They enable the manufacturing of:

- Engine parts

- Transmission shafts

- Precision components for vehicle bodies

The aerospace industry benefits especially from the precision of these machines. Industry 4.0Technologies enable the production of highly complex components for aircraft and spacecraft with the highest precision.

In medical technology, CNC machining centers guarantee the production of life-saving devices and implants. The manufacturing technology ensures:

- Absolute accuracy

- Sterilizable surfaces

- Complex geometric structures

The integration of these machining centers into modern production environments not only optimizes manufacturing processes but also reduces production costs and increases the quality of the end products.

Conclusion on the CNC machining center

CNC machining centers revolutionize the modern manufacturing industry with their unparalleled precision and efficiency. The future of manufacturing is heavily influenced by these advanced technology systems that simplify and optimize complex production processes.

The technological advancement continuously drives the development of these machines. Companies need to adapt to the growing demand for skilled workers and specifically train employees for operating and programming these complex systems. Qualified professionals are the key to successful utilization of modern CNC technologies.

The integration of artificial intelligence and machine learning promises further innovations in CNC technology. These developments will make manufacturing processes even more precise, faster, and more flexible, providing United States companies with a decisive competitive advantage in the global market.

In summary, CNC machining centers are not only a technology but also a strategic tool for future-oriented manufacturing companies. They embody the symbiosis of human expertise and technological innovation.