CNC programming revolutionizes the modern manufacturing industry through computer-controlled precision technology. It enables highly automated and efficient production in various industries such as machinery, automotive, and aerospace sectors.

CNC technology stands for computer-controlled manufacturing, where complex machines are operated by digital programming commands. This innovative method allows for precise and repeatable production of components with the highest accuracy.

Companies use CNC programming to reduce production costs, shorten manufacturing times, and ensure consistently high quality. The technology has become a key element of modern Industry 4.0.

Key findings

- CNC programming enables highly precise automated manufacturing

- Digital control increases production efficiency

- Applicable in various industries

- Reduces human error rates

- Supports complexity and precision in manufacturing processes

Definition of CNC programming

CNC programming is a revolutionary technology in the modern manufacturing industry. It stands for "Computer Numerical Control" and transforms the way machine tools are controlled. At its core, numerical control enables precise and automated control of production processes.

The basic idea of CNC control is based on computer-aided programming of machines. Complex work steps are controlled by digital commands, enabling highly precise manufacturing of components.

- Automation of manufacturing processes

- Highest precision in processing

- Reduction of human error sources

- Complex processing steps are simplified

The development of CNC technology began in the 1950s and has since completely transformed machine tools. From manual controls, the technology evolved into highly complex computer-aided systems that are now used in almost all industrial manufacturing sectors.

CNC programming means precision, efficiency, and technological innovation in modern manufacturing.

Compared to traditional manufacturing methods, CNC programming offers significant advantages: it enables much more precise processing, reduces production times, and minimizes material waste.

Components of CNC programming

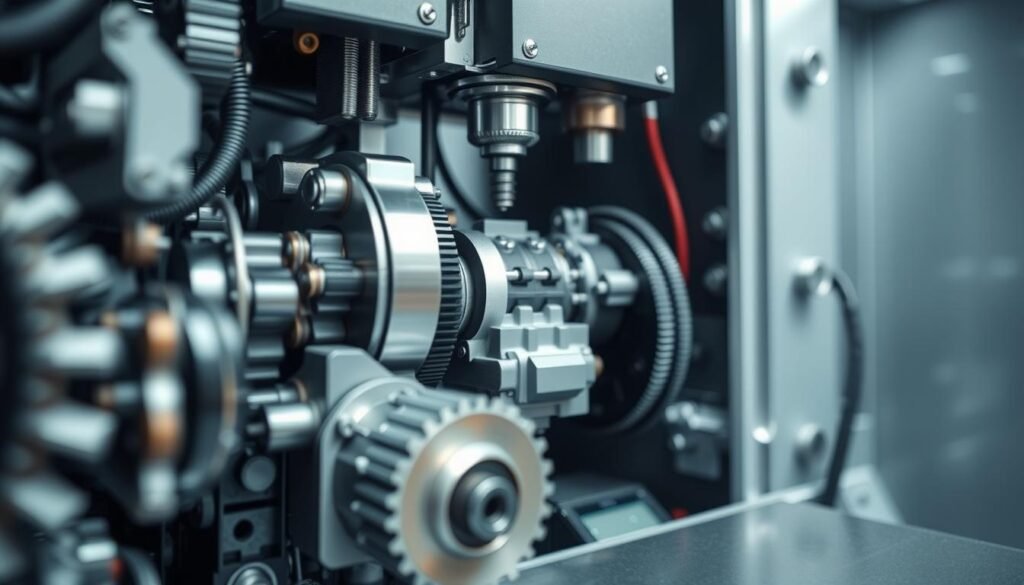

The CNC programming includes various complex components that work together to enable precise and efficient manufacturing processes. Modern industrial companies rely on advanced technologies to optimize production workflows.

CNC Machines: Precision Manufacturing Tools

CNC milling machines and CNC lathes form the backbone of modern metalworking. These precision instruments enable highly accurate manufacturing of components with minimal tolerances.

- CNC milling machines for complex shaped parts

- CNC lathes for rotationally symmetric workpieces

- Processing centers for comprehensive manufacturing processes

Programming and control

The control of CNC machines requires precise programming. Technicians use specialized software solutions to define movement sequences and processing steps accurately.

G-Code as a programming language

The G-Code It is the central programming language for CNC machines. It translates technical instructions into concrete machine actions and controls movements with the highest precision.

Use of CAD/CAM software

CAD/CAM systems simplify the programming of machining centers. They enable a seamless transformation of digital design drawings into machine-readable manufacturing instructions.

Modern CNC technologies combine precision, efficiency, and innovation in industrial manufacturing.

Conclusion on CNC programming

CNC technology has fundamentally changed modern manufacturing. The future of CNC technology lies in the advancing digitalization and networking of production systems. Companies are increasingly relying on state-of-the-art manufacturing solutions that maximize precision and efficiency.

Industry 4.0 is significantly advancing the development of CNC systems. Intelligent production equipment is being equipped with artificial intelligence and machine learning. These technologies enable self-optimizing manufacturing, reducing error rates and conserving resources.

Digital manufacturing requires highly skilled professionals. CNC programmers play a key role in modern industrial companies. The demand for experts with advanced programming skills is continuously increasing. Training and further education in this field offer excellent career opportunities.

The technological advancement will further revolutionize CNC programming. Companies that invest early in these technologies secure critical competitive advantages in an increasingly digitalized global economy.