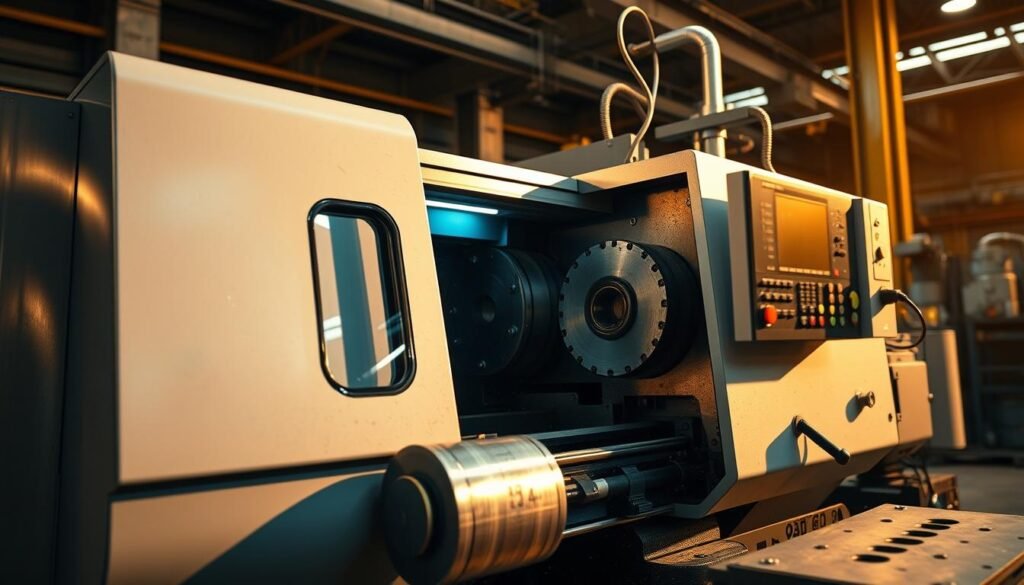

CNC turning is a highly precise manufacturing technique in which computer-controlled machines machine metal parts with exceptional accuracy. The CNC lathe enables a revolutionary method of metal processing that far surpasses traditional manual techniques.

The computer-controlled turning uses advanced CNC technology to manufacture complex workpieces. Precise numerical control systems allow for highly accurate machining of metal components with minimal human intervention.

This innovative manufacturing method is used in numerous industries, from the automotive industry to medical technology. The technology enables the production of complex parts with the highest repeatability.

Key findings

- CNC turning uses computer-controlled precision technology

- Enables high-precision metal processing

- Reduces human error rates

- Applicable in various industries

- Significantly increases production efficiency

Computer-controlled precision in CNC turning

CNC precision turning revolutionizes modern manufacturing processes through its unique combination of technology and accuracy. Computer-controlled systems enable unprecedented control over machining processes, far surpassing traditional manufacturing methods.

High precision and repeatability

Automated manufacturing through CNC technology guarantees exceptional repeatability. Machine systems can minimize microscopic deviations and produce identical workpieces with the highest precision.

- Precision up to 0.01 mm

- Constant quality assurance

- Minimal manufacturing tolerances

Automated process

CNC turning transforms industrial manufacturing processes through fully automated workflows. Computer-controlled systems reduce human error rates and significantly increase efficiency.

| Property | Traditional manufacturing | CNC-Präzisionsdrehen |

|---|---|---|

| Precision | ±0.1 mm | ±0.01 mm |

| Production speed | Slowly | Very fast |

| Error rate | High | Very low |

The technology enables a precise and repeatable manufacturing, which has become essential in modern industries.

Material removal during CNC turning

The machining process in CNC turning is a precise mechanical operation in which material is selectively removed from a workpiece. This process enables the production of complex and highly accurate components in various industrial sectors.

Tool cutting: The foundation of precision

Cutting tools play a crucial role in material removal. They are designed to precisely and efficiently remove material layers from the workpiece surface. The selection of the right tool directly affects the quality and accuracy of the workpiece machining.

- Carbide cutting inserts for hard materials

- Ceramic tools for heat-resistant applications

- Diamond-coated tools for high-precision machining

Movement along the workpiece surface

The movement of the cutting tool follows mathematically calculated paths. CNC controls enable extremely precise positioning and movement, ensuring uniform and error-free processing.

| Movement type | Function | Precision |

|---|---|---|

| Longitudinal section | Removal along the workpiece longitudinal axis | Very high |

| Cross-section | Processing of the workpiece width | Exact |

| Contour cut | Complex geometric shapes | Highest precision |

Rotation-symmetric components through CNC turning

CNC turning enables the production of precise rotationally symmetric components with the highest accuracy. This manufacturing technique is especially suitable for complex parts that require perfect roundness and symmetrical structure.

The wave production through CNC turning offers significant advantages for various technical applications:

- High-precision geometries

- Uniform material processing

- Minimal manufacturing tolerances

Waves and axes in focus

With the thread-turning technology, different shaft types with complex cross-sections and surface structures can be manufactured. The rotational symmetry allows for uniform material processing and guarantees optimal mechanical properties.

Round shapes and precision

CNC turning allows the production of highly precise round shapes with extreme accuracy. Through computer-controlled movements, even complex geometric structures can be implemented exactly.

The precision of CNC turning revolutionizes modern manufacturing technology.

Versatile applications of CNC turning

CNC turning has established itself as a key technology in industrial manufacturing. The precision and flexibility of this manufacturing method make it essential for various industries. Companies use CNC turning to produce high-quality precision parts with complex geometries.

The variety of CNC turning applications spans several key industries:

Automobile manufacturing

- Manufacturing of engine components

- Precise axes and shafts

- Complex transmission parts

Mechanical engineering

- Precise connecting elements

- Industrial drive shafts

- High-strength machine components

Medical technology

- Surgical Instruments

- Implants with the highest precision

- Medical precision parts

Electrical engineering

- Electrical contacts

- Connector

- Complex electronic components

The technology of CNC turning enables companies to high-precision components to develop that meet the strictest quality requirements.

From the design to the workpiece with CNC turning

The path from digital design to precise workpiece is a fascinating process in modern manufacturing technology. CAD/CAM software plays a key role by translating complex digital designs into exact manufacturing instructions.

Digital Construction Process

The first step begins with creating detailed 3D models in professional CAD/CAM software. Designers use powerful tools to precisely design rotationally symmetric components.

- Digital 3D modeling creation

- Geometric precision planning

- Virtual processing simulation

Precise manufacturing processing

The CNC programming converts these digital designs into precise manufacturing processes. Modern CNC machines interpret the program data and execute them with the highest accuracy.

- Conversion of the 3D model into CNC commands

- Automatic tool selection

- Precise material removal

The digital workflow enables flexible and efficient production of complex workpieces with minimal human intervention.

Conclusion on CNC turning

CNC turning has established itself as a key technology in modern manufacturing industry. The advantages of CNC turning are diverse: high precision, efficiency, and flexibility in production. Companies can produce complex workpieces with the highest accuracy and at the same time reduce production costs.

The future of manufacturing clearly lies in automation and digital integration. In the context of Industry 4.0, CNC turning plays a central role. It enables seamless networking of production steps and helps companies stay competitive. Digital manufacturing technologies like these are revolutionizing industrial production.

Technological innovations in CNC turning will further optimize manufacturing processes. Precision, speed, and flexibility will continuously improve. For companies, this means not only an increase in productivity but also the opportunity to produce more complex and customized components.

Skilled workers who master CNC turning technologies will become increasingly in demand in the industry. The technology offers exciting career prospects and emphasizes the importance of continuing education in technological advancement.